Product Details

An inlet vane damper, also known as a variable inlet vane (VIV) damper, is a crucial component in optimizing airflow within various systems

Description

Inlet Vane Damper: Controlling Airflow Efficiency:

An inlet vane damper, also known as a variable inlet vane (VIV) damper, is a crucial component in optimizing airflow within various systems. Here’s a detailed breakdown of its features and functionalities:

Functions of inlet vane Damper

Installed at the inlet of fans, blowers, or air handling units (AHUs) in ventilation and air conditioning systems.

Regulates the volume of air entering the equipment by adjusting the angle of multiple vanes (blades) within the damper housing.

Offers precise control over airflow, leading to several benefits.

Components of inlet vane Damper

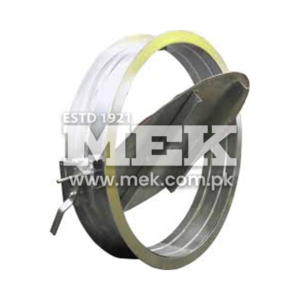

Damper Housing: Typically constructed from sturdy materials like galvanized steel for durability.

Vane Assembly: Consists of a series of individual vanes (usually airfoil-shaped) that rotate around a central axis.

Actuation Mechanism:

Manual: Uses a lever or handwheel for direct control.

Automatic: Employs a motor or actuator linked to a control system (e.g., temperature sensor, pressure sensor) for automated adjustment.

Combination: May offer both manual and automatic operation for flexibility.

Operation of inlet vane Damper:

By adjusting the vane angle:

Open position: Vanes are aligned parallel to the airflow, allowing unrestricted air intake.

Closed position: Vanes are positioned perpendicular to the airflow, significantly reducing or completely stopping air intake.

Partially open positions: Vanes create varying degrees of restriction, enabling precise control over airflow volume.

Benefits and Applications of inlet vane Damper

Benefits of inlet vane Damper:

Improved System Efficiency: Optimizes fan and AHU performance by matching airflow to system requirements. This reduces energy consumption and operating costs.

Demand-based Ventilation: Allows for adjustments based on occupancy or changing ventilation needs.

Reduced Noise Levels: Optimized airflow can minimize turbulence and noise generation within the system.

Process Control: Enables precise control over air volume for specific industrial processes requiring consistent airflow.

Applications of inlet vane Damper:

Widely used in HVAC systems of commercial and industrial buildings.

Found in industrial applications like dust collection systems, fume exhaust systems, and process air control.

Utilized in power plants and other facilities requiring efficient air management.

Additional Considerations: for of inlet vane Damper

Damper Size: Selected based on the duct diameter or equipment inlet size.

Material Selection: Depends on factors like operating temperature, pressure, and potential corrosion concerns.

Control System Compatibility: Ensures seamless integration with existing control systems for automated operation.

Maintenance: Regular inspection and cleaning of the damper mechanism are recommended for optimal performance.

By understanding the detailed features and functionalities of inlet vane dampers, you can leverage their capabilities to optimize airflow control within your ventilation and air handling systems, leading to improved efficiency, cost savings, and better process control.